News

fima at electronica 2024

We're thrilled to announce that we'll be exhibiting at the Electronica Fair in Munich, Germany, from November 12-15, 2024! This year marks not only our 50th anniversary of producing high-quality PCBs but also our long-standing participation in this prestigious event.

New ECOSPRAY machine & Thermal Oven

Our brand new spray coating system features an SFS system (Spray-Flip-Spray),

automatic panel loading and unloading in-line with EcoDryer, simple maintenance and

cleaning, a large PLC screen and recipes with joblist, up to three heated guns with low

overspray, automatic color change and cleaning (optional), excellent gap filling and

encapsulation with ±80% transfer efficiency and productivity of 20-30 double-sided

coated panels per hour with a 100g/m2 ink deposit.

TheEcoDryer is a conveyorized oven for tack drying of solder masks in combination with

Ecospray. It features dynamic hot air drying,

a dedicated air circulation system, and a dedicated fan for cooling the panel.

fima at Focus on PCB 2023

This year, Fima will take part in "Focus on PCB" 2023, the Italian Fair of PCBs. Come visit us in Vicenza on May 17-18 at Pavilion 1, Stand 114.

New SOLDER DEVELOPMENT Machine

Fima doubles up with the purchase of another Wise machine! This time with the objective of improving solder development. The Solderstar will let us achieve better results thanks to its improved technology, which lets us obtain a perfect definition and uniform coverage of the solder on the PCB.

New SURFACE TREATMENT Machine

Fima wants to improve its surface treatment department with a new Wise machine. The Chemstar Ultraflex is a new machine that will allow us to get even better results. Thanks to the newly improved motorization system that will minimize eventual drag out of the PCB and will prevent panel bending issues, ensuring a very smooth end result.

fima at electronica 2022

This year, Fima took part in "Electronica" 2022, the international trade fair for electronic components.

New ROUTING Machine

The routing machine family gets bigger! Fima wants to improve its milling department with one of the newest routing machines on the market. The "C2" machine by Pluritec will let us raise our product quality thanks to the improved accuracy and speed of the linear motor that drives all axes and the two independent heads, each with its own dedicated motor.

New DRILLING Machine

In order to enhance the drilling department, Fima decided to invest in the new Inspecta Combo by Pluritec. The highest accuracy and stability in combination with maximum versatility and flexibility, together with the patented "One Step X-Ray Drilling and Routing" function, will let us provide you with top-quality products. This new function allows the machine to perform local image target detection, deformation compensation (linear and non-linear rotation) and direct drilling or routing on your job with the best possible annular ring.

New ELECTRICAL TEST Machine

Having focused his production on prototypes and a high technological level, Fima was looking for an electrical machine tester able to satisfy both requirements. Because of its flexibility, ATG A7 matches these needs. Its speed, a big tester area, multiple parallel loading and its already known precision make this machine the right choice for the development of its electrical test department.

fima at electronica 2018

Also this year, Fima took part in "Electronica", the 28th International Trade Fair for Electronic Components, Systems and Applications, in Munich, Germany. Fima has shown all the new investments made this year. They have been focused on increasing quality, productivity, and technology.

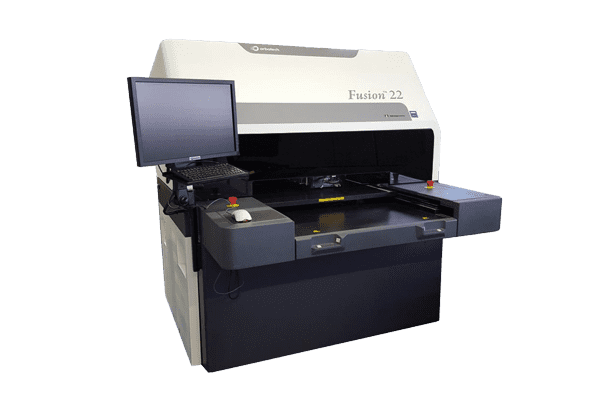

New AOI Machine

In order to increase the AOI department's throughput, Fima decided to increase its available machine number by buying an Orbotech AOI of the Fusion series. Fusion is able to inspect a panel using multiple light sources in one scan for unparalleled detection accuracy. Designed for high-end HDI and MLB applications, Fusion matches exactly Fima's technological requirements.

New DI Machine

Taking evident advantage of its continuous investment process, Fima decided to improve its printing department by inserting a new direct imaging machine into the production flow. It is an APOLLON of the Printprocess company. Its versatility gives Fima the possibility to print solder masks as well as inner or outer layers with very high precision. The simple tooling and the automatic loader and unloader significantly increase Fima's productivity in this fundamental department.

New ITC Holes Plugging Machine

Fima keeps improving with its latest investment: the new Double Plugging Machine represents another step forward in PCB manufacturing with an innovative hole plugging process. Fima is now capable of applying conductive and non-conductive paste with a specially designed process that makes it possible to avoid the formation of air bubbles in the holes. A whole new level of productivity is also granted thanks to the 5kg capacity of the storage container. The possibility to work on both stations simultaneously, although using two different programs, ensures high quality even without renouncing high-speed production.

New Galvanic System

In the interest of improving the galvanic processes and ensuring working continuity, Fima decided to implement a new galvanic system. Its total automation, the vibration systems and the floating bars are just some of the peculiarities that mark this machinery, which also assures special consideration for the operator's safety. Caoduro Galvanic System pays particular attention to the surrounding working environment.

New Base Material Automatic Magazine

In order to optimize its productive process, Fima focused on an aspect that is too often considered of secondary importance: logistics. That is the reason why a new automatic magazine has been implemented. Fast, accurate and practical, the new Vertimag Bertello has significantly affected production timing, simplifying the stocking of laminated base materials.

New Routing Machine With Automatic Optical Alignment

Fima never stops investing. Thanks to a recently installed milling machine, it is now possible to mill PCBs with automatic alignment driven by a CCD camera. This way, FIMA guarantees to satisfy the tightest dimensional tolerances. This equipment also makes it possible to carry out Z-axis-controlled counterbores with a still unbeaten precision of +/-10 µm.

New Laser Drilling Machine "Nanoflex UV Drilling System"

Innovation, advanced technology and focused investments play a key role in the strategy of each company today. Fima considers them a base to assure a smart organization that satisfies the requirements of an innovative market. Fima has achieved a significant result in this strategy by purchasing the new LASER DRILL MACHINE, thus improving its competitive value in the production capability of high technology PCB's. A small step in our strategy leads to a big step in your technology.

New Three Guns Air Spray Machine for solder mask

Beside our green solder mask line, a second air spray machine is available to deposit colored solder masks. With three different guns and three separate hydraulic circuits, this equipment allows us to spray colored solder masks (white, black, red, blue and yellow) without interfering with the normal production.

ISO 26000:2010

Even when the world economy proves itself far from favorable, Fima perseveres in its steps forward in investment and innovation by paying due attention to aspects often wrongly considered less important. With great satisfaction, we disclose that ECOVADIS and SCHNEIDER acknowledged that Fima works in respect of the policy ISO 26000:2010 on the social responsibility of organizations (environment, safe working practices, fair trade practices, sustainability).

fima preferred supplier

For the second time, the French international group Schneider Electric officially recognized Fima as the best supplier of the year. This feedback is based on quality, timing and efficiency in communication. Our quality system puts forth daily efforts to satisfy our customers' requests. FIMA is very proud to receive this reward in a competition where also bigger and internationally renowned companies take part. FIMA is a perfect demonstration that the dimensions of a company are not directly proportional to its technological and qualitative efficiency.

Internship in fima

Since this year, Fima has decided to use the new regulatory instruments to combine education and work. Fima gives high school graduates with technical education or experience the opportunity to join our team. The possibility to work in Fima allows young students with no or little working experience to get familiar with the dynamics of an industrially productive reality that is becoming increasingly international.

fima at electronica 2014

Fima took part in the 26th International Trade Fair for Electronic Components, Systems and Applications last November in Munich, Germany. Even in this edition, Fima showed its experience to players from all over Europe. Our company is able to combine high-quality products, technology and flexibility thanks to its relatively small dimensions.